As the world’s most trusted source for 3D measurement technology, FARO has endeared itself to major contractors and projects around the world through its offering of portable coordinate measuring machines and 3D imaging devices that solve dimensional metrology problems.

From its Asia-Pacific headquarters in Singapore, the US Group’s subsidiary’s portfolio of products enable users from a variety of markets to perform high-precision 3D measurement, imaging, and comparison of parts and compound structures within production and quality assurance processes.

Subsequently, this allows companies to maximise efficiencies and improve processes, and with FARO’s products having been applied to numerous industry verticals as a consequence, its geographic footprint and project portfolio have also expanded simultaneously.

“FARO has served Asia since 2000, locating its first regional branch outside of the US in Japan,” the Company’s Head of Marketing, Quah Beng Chieh says. “The Company has since expanded rapidly to establish 15 facilities across Singapore, Japan, China, India, South Korea, Thailand, and Australia.

“These branches cover a full suite of services and functions including sales, operations, finance, marketing, customer support, logistics, and servicing. FARO’s expansion over the years in Asia has enabled us to provide closer and better support to our growing customers in this region.

“FARO treats each project as a priority, and we do our best to cater to our customers’ requirements. Some notable projects include the scanning of India’s Roorkee Railway Station, Niah Caves documentation in Malaysia, Cyark scanning of the Sydney Opera House in Australia, and manufacturing of an Osaka University race car in Japan. FARO’s technologies can be used to support a wide variety of industries and different purposes, and we are proud to add value to these notable projects.”

Q&A WITH QUAH BENG CHIEH, FARO

As one of these key projects, can you please talk me through FARO’s contribution to India’s first ever R&D project devoted to modernising the country’s railway infrastructure?

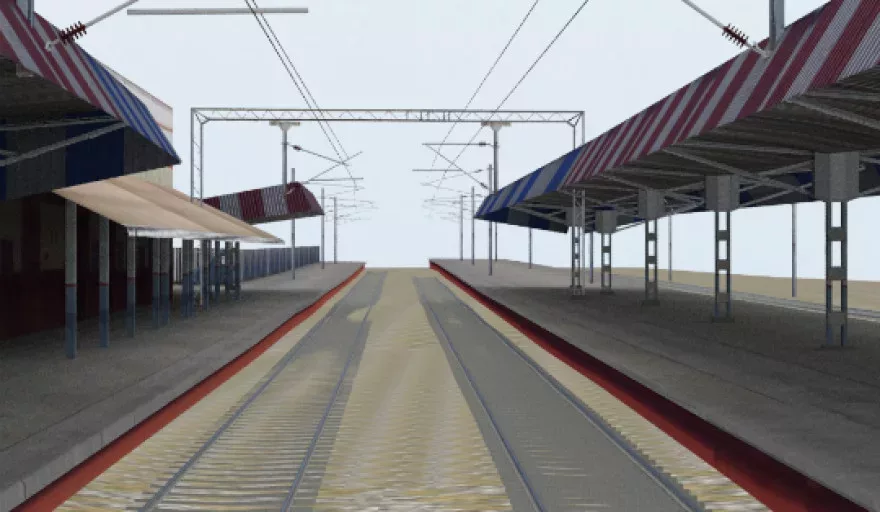

Quah Beng Chieh (QBC): Last year, FARO supplied researchers from the Indian Institute of Technology Roorkee (IIT Roorkee) with the FARO Laser Scanner Focus3D X 300. The goal was to provide the Ministry of Railways with insights on India’s current railway infrastructure and recommendations for improvements on the tracks, signalling, stations, and terminals. A first of its kind, the research would help shape the country’s future railway infrastructure, and would require accurate and objective results to facilitate progress.

Using the compact and lightweight Focus3D, the team of researchers completed the task of scanning the Roorkee Railway Station in just 10 days, a task that could have otherwise taken 30 days. The Focus3D performs well even under direct sunlight and this feature proved to be vital for the team, as it enabled them to acquire data quickly and accurately regardless of lighting conditions.

In addition to providing point cloud data simultaneously with every scan, the Focus3D also offered the client with a complete stitched 3D map,enabling the Government to easily integrate the map into a 3D smart city data file for the country.

We are encouraged by the success that IIT Roorkee achieved, and FARO will continue to share its expertise with various partners.

How do you foresee the role of 3D measurement, imaging and realisation technology evolving in the years to come via projects such as these?

QBC: We expect that future projects and product designs will become more complex. This will influence manufacturers to change and evolve to retain their competitive edge in their respective markets. At the same time, companies will also demand for more advanced technologies to support their goals.

This impacts FARO, as we believe that demand for innovative technologies will drive greater demand on the requirements and specifications of future 3D measurement, imaging, and realisation devices. Technologies will become more multi-functional and cross-functional, with greater accuracy, lower cost, smaller form factors, higher efficiency, and measurement effectiveness. For example, we can possibly expect the integration of several platforms and technologies to form new solutions such as unmanned aerial vehicle (UAV)-scanning or inspection systems for hard-to-reach places such as dams, or fully autonomous remote scanning or measurement solutions to perform tasks in hazardous environments.

As FARO strives to anticipate the evolving needs of its customers and of the industry, we must consistently invest in research and development (R&D) activities to design products that feature the most cutting-edge technologies. This was how FARO developed the FARO® Cobalt Array Imager and the FARO® TracerM Laser Projector. The former features on-board processing, an industry first, which enables unique multi-image array configurations, expanding the scan area to deliver rapid and automated inspection of all surfaces of an object, dramatically reducing cycle time. The latter eliminates the need for physical templates with virtual templating and positioning solutions, streamlining a wide range of assembly and production applications.

What projects are in FARO’s pipeline for the rest of 2017, and how do you expect to see the extent of 3D technologies being used evolve in the future?

QBC: FARO caters to a wide variety of markets such as the automotive, construction, die-and-mould, heavy machineries, and metal fabrication industries. In 2017, FARO will continue to support these and other sectors with our expertise and technologies, as we target to also explore new projects.

Our solutions are used in multiple projects around the world, and across different industries and applications. As shared earlier, FARO’s solutions have enabled IIT Roorkee to gather information on India’s railway infrastructure. Our technologies have also been used to support different aspects of India’s Smart Cities Initiatives, such as the revamping of railways and buildings. With the India government pushing for infrastructure investments, the immediate future is bright for companies operating in the industrial manufacturing and construction segments, and FARO will be on hand to provide manufacturers with advanced metrology and scanning support where needed.

I would expect [in the future] that our customers will see more new and diverse application technologies to keep up with the changing market demands, especially in fast developing countries or regions such as India and Southeast Asia.